Tutti i prodotti compositi sviluppati e prodotti da Crossfire sono totalmente esenti da solventi e non rilasciano VOCs (volatili organici). Sia gli articoli a fine vita che gli scarti della loro lavorazione, essendo basati su Crosspreg® e/o CrossLam, possono essere riciclati per macinazione meccanica e quindi utilizzati direttamente nella produzione (compounding) di plastiche termoplastiche rinforzate per iniezione.

Anche i sandwich di Crosspreg® e CrossLam con core in PET sono riciclabili nello stesso modo, ossia per macinazione integrale e conseguente compoundazione. Questa tecnologia di riciclabilità è stata verificata presso i laboratori R&D della società Samyang Corporation, nostro partner (l’attestato ufficiale è disponibile a richiesta).

Crosspreg® è un prepreg reattivo ma è stabile a condizioni RT quindi non necessita di consumare energia in stoccaggi frigoriferi. Crosspreg® e CrossLam sono prodotti con tecnologie a bassa domanda energetica e conseguentemente sono altamente competitivi sul mercato. Entrambi sono prodotti industrialmente.

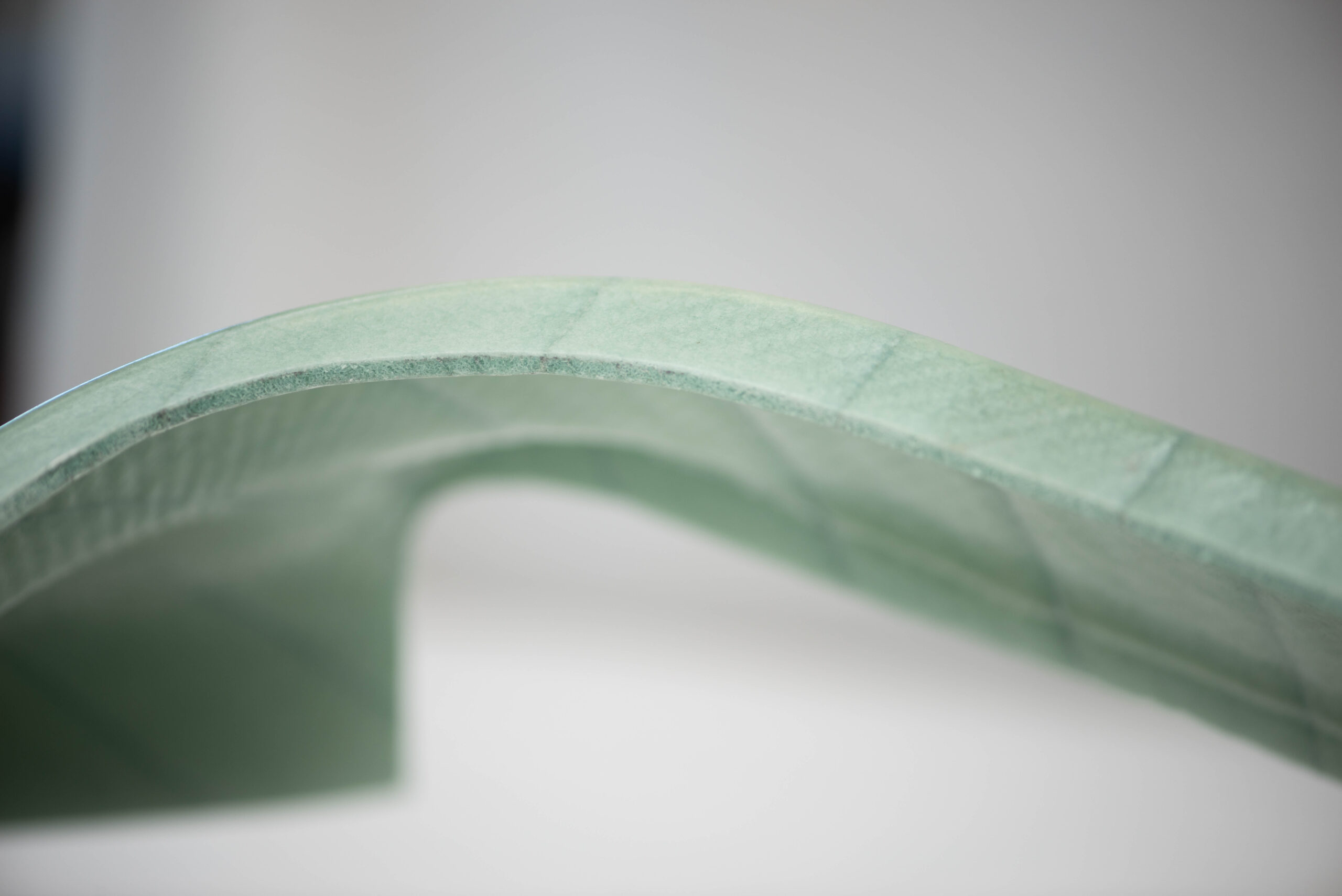

La principale caratteristica di Crosspreg® e CrossLam è la loro capacità di generare processi di formatura per processi di elevata sequenzialità tramite stampaggio isotermico in pressa. Il tempo di consolidamento è molto breve, da poche decine di secondi a pochi minuti a seconda dei casi; ciò rende l’intero processo capace di una richiesta di energia molto contenuta.

Crosspreg® e CrossLam rappresentano la nostra risposta verde alla tradizionale tecnologia dell’acciaio che richiede elevati consumi di energia dalla creazione dei materiali alla loro trasformazione: ciò è possibile grazie alla producibilità di componenti strutturali leggeri senza comprometterne la solidità meccanica di specifica. Inoltre, Crosspreg® e CrossLam, grazie alla loro natura di tessuti, possono essere isotropici oppure anisotropi secondo quanto le specifiche costruttive del componente possano richiedere in termini di orientamento ed intensità dello stress secondo gli studi FEM.

I manufatti prodotti tramite Crosspreg® e Crosslam soddisfano tre necessità fondamentali :

• La loro produzione tramite linee produttive a bassa intensità di capitali

• Una crescente competitività all’aumentare dei volumi

• La fattibilità di componenti più robusti, esenti da ruggine, e capaci di lunga vita operativa, rispetto agli attuali (pannelli strutturali per edilizia, mobili, container, componenti sagomati, componenti per uso marino, ..)

Servizi Crossfire

Crossfire sviluppa ed avvia nuove e innovative tecnologie nate sia da idee interne che da richieste e progetti dei clienti.

Offre la propria consulenza riguardo le diverse tecnologie di produzione con materiali compositi; inoltre sviluppa e genera prototipi al proprio interno, per verificare e testare le caratteristiche di specifica allo scopo di raggiungere i requisiti richiesti.

Crossfire supporta il cliente nella pianificazione e scelta delle linee industriali di produzione in linea con i target del progetto.

Crossfire è onorata della partnership con Orma Macchine, società italiana leader nella produzione e fornitura di presse idrauliche, nel progettare e adattare le linee produttive alle esigenze del singolo cliente.

English

English